1d bend, 2d bend, 3d bend, 5d bend, 10d bend, 12d bend And Long Radius Bend Manufacturer in India, Mumbai, UK, USA, China, UAE

Table Of Content

Long Radius Bend Manufacturer in India

Fitwel Industries LLP is a one of the leading professional long radius bend manufacturers, suppliers & exporter of long radius bend with precision machining facilities. We produce long radius bend as per ANSI B16.29, ASTM A53/A106, ASME B16.28 standard in size range of 1/2” to 36”. Our ANSI/ASME B16.9 long radius bend and other fitting products are manufactured using quality material and go through a best quality check at all stages of production to ensure quality.

Designed in compliance with international quality standards, these ANSI/ASME B16.9 long radius bend are corrosion resistance, sturdy and durable. We also manufacturer ANSI/ASME B16.9 Long Radius Bend, 5d bend, 2d bend, 10d bend and other pipe fittings in customized size. We produce fittings in carbon steel, stainless steel, high nickel alloys, duplex/super duplex, copper nickel, titanium and special alloys. This Long Radius Bend Long Radius Bend, 5d bend, 2d bend & 10d bend are designed with precision in consonance with the international quality guidelines and norms, employing advanced manufacturing techniques. These 2d bend manufacturers is available in various forms, grades as per the clients’ requirements. Our Long Radius Bend manufacturers is also being offered at best possible rates. 5d bend manufacturers is a kind of fittings that are used for industrial purposes, and we manufactures it with excellent efficiency. They connect two different pipes at an angular formation and give an angular direction to the flow in the pipes. They are majorly used in the piping systems for its peculiar qualities. 10d bend manufacturers is divided into its radius of curvature and then are distinguished as long radius and short radius. They are one of the most effective and durable fittings to connect other outlets for its directional flow. We are Long Radius Bend Suppliers in India in various sizes and are produced in abundance as per the specified requirements of the clients.

Fitwel Industries LLP is one of the leading Manufacturer of Long Radius Bend in India. We also manufacturer the 1.5D Bend, 2D bend, Long Radius Bend, 5D Bend, 8D Bend, 10D Bend & 12D Bend in India. We are an award-winning Supplier of Long Radius 3D/5D/10D/12D Bend in India, and we are ISO Certified and the best quality product Exporter of Long Radius 3D/5D/10D/12D Bend in India. Trader of Long Radius 3D/5D/10D/12D Bend in India and provide our products to clients in a combination of good grades, thickness, length, and surface finish. To fulfill emerging customer's needs we started working as a distributor and become the largest Distributor of Long Radius Long Radius Bend in India.

Fitwel Industries LLP is the Largest Stockiest of Long Radius 3D/5D/10D/12D Bend in India. We are continuously expanding our product line as a Stockholder of Long Radius 3D/5D/10D/12D Bend in India, Trader of Long Radius 3D/5D/10D/12D Bend in India and provide our products to clients in a combination of good grades, thickness, length, and surface finish. We Manufacture a wide range of Buttweld Bend (ASTM A403 & ASME SA403, ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-43), SS Buttweld Pipe Bend Exporter in India, Stainless Steel Buttweld Long Radius Bend, Buttweld 3D/5D/10D/12D Bend, ASTM A403 LR Pipe Bend, ASME B16.9 Buttweld Bend, Buttweld Pig gable Pipe Bends, Hot Bend Stockholder, Buttweld 3D/5D/10D/12D Pipe Bend Dealers, Carbon Steel Induction Bend Distributors, Alloy Steel Buttweld 3D/5D/10D/12D Bend in Saudi Arabia, Nickel Alloy Buttweld 3D/5D/10D/12D Bend Suppliers & Inconel Buttweld 3D/5D/10D/12D Bend in India, UAE, Dubai.

Fitwel Industries LLP is a well-known exporter, manufacturer, and supplier of Long Radius Bend worldwide in the steel market industry. The purpose of Radius Pipe Bend is to amend the direction and flow through a 180-degree angle. Coming in two important forms of Bends – short radius bend and long radius bend – to which both of them are having a midpoint-to-midpoint length, along with double the indistinguishable 90-degree elbow. The most important application for these pipe fittings is in heater coils and heat exchangers. Buttweld Pipe Fittings Long Radius Bend is manufactured with dissimilar grades of standard ranges and meets its provisions through international and national standards. They are quite unproblematic to remove and install and can be accessible to our customers in diverse technical specifications of sizes and threading as per necessity.

What is Long Radius Bend?

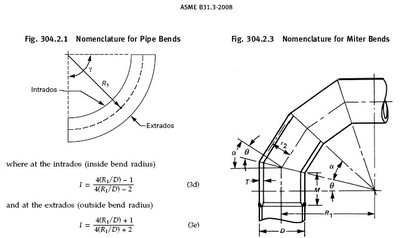

The long radius bend/elbow refers to the outer diameter of the tube whose radius of curvature is equal to 1.5 times, that is, R = 1.5D. It does not represent the inner diameter of the pipe or the outer diameter of the pipe. It is a nominal size designed and used.

Long Radius Bend manufacturers in India is a generic term for any offset or change of direction in the piping. It is a vague term that also includes elbows. Bends are generally made or fabricated as per the need of the piping; however elbows are pre-fabricated and standard, and are available off the shelf. Bends are never sharp corners but elbows are. Pipe bending techniques have constraint as to how much material thinning can be allowed to safely contain the pressure of the fluid to be contained. In bends as the pipe is bent and there is no welding involved, there is less pipe friction and flow is smoother.

The pipe bends should be as per the standard of ANSI/ASME B16.49 which did not specific the bending radius and angle, the regular pipe bend radius are 2.5D, 3D ,5D ,7D or 8D , but it can be any other bending radius according to the design need, and bending angle can be in any degree, 5 ,10 ,15, 90 degree or any other. People said “All bends are elbows but all elbows are not bend”, it is not true. Actually “All elbows are pipe bends but not all bends are elbows” is more reasonable.

How Long Radius Bend is Different From Elbow?

The most basic difference of them is the elbow relatively short than bend, R = 1D to 2 D is elbow More than 2D is bend. In the production process, cold bends can use Bending Machine to bend by ready-made straight bend. One-time completed also don’t need second corrosion. But elbow need manufacturers make to order, to do anti-corrosion, order cycle is long. Elbow price is higher than bend. But cost performance is much higher than bend. It is well-known that bend do not have anticorrosive processing is easy damaged, but the price is cheap so are used very much in some demand which not very high engineering.

In the west-east gas transmission of course, cold bends cost is low. elbow need manufacturers make to order, needs corrosion, order cycle is long,but cold bends can use ready-made straight bend by Bending Machine to bend. One-time completed also don’t need second corrosion. The cold bend construction technology need follow oil standard .west-east gas transmission have the enterprise standard,but we can use either elbow nor bend in open area. Sunny Steel Enterprise warn broad customers betweenness elbow and bend performance price is differ ,please carefully choose after consider it.

Difference between a pipe elbow and a pipe bend is as follows:

Pipe Bend is a generic term for any offset or change of direction in the piping. It is a vague term that also includes elbows.

An elbow is an engineering term and they are classified as 90 deg or 45 deg, short or long radius.

Pipe elbows have industrial standards and have limitations to size, bend radius and angle. The angles are usually 45 deg or 90 degrees. All others offsets are classified as pipe bends.

Bends are generally made or fabricated as per the need of the piping; however elbows are pre fabricated and standard, and are available off the shelf.

Bends are never sharp corners but elbows are. Pipe bending techniques have constraint as to how much material thinning can be allowed to safely contain the pressure of the fluid to be contained. As elbows are pre fabricated, cast or butt welded, they can be sharp like right angles and return elbows which are 180 degrees.

Elbow is a standard fitting but bends are custom fabricated.

In bends as the pipe is bent and there is no welding involved, there is less pipe friction and flow is smoother. In elbows, the welding can create some friction.

All elbows are bends but all bends are not elbows.

Bend has a larger radius then elbows.

Generally the most basic difference is the radius of curvature. Elbows generally have radius of curvature between one to twice the diameter of the pipe.

Bends have a radius of curvature more than twice the diameter.

Long Radius Bend Dimensions

Long Radius Bend are used for:

There is a need to keep the frictional fluid pressure loss down to a minimum;

There is ample space and volume to allow for a wider turn and generate less pressure drop;

The fluid being transported is abrasive or has solids in it.

Dimensions ButtWeld Elbows/Bend 45°-90° LR and 3D ASME B16.9

| NPS |

O.D.

D |

90°

Long Rad

Center to End

A |

45°

Long Rad

Center to End

B |

90°

3D

Center to End

A |

45°

3D

Center to End

B |

| 1/2 |

21.3 |

38 |

16 |

|

|

| 3/4 |

26.7 |

38 |

19 |

57 |

24 |

| 1 |

33.4 |

38 |

22 |

76 |

31 |

| 1¼ |

42.2 |

48 |

25 |

95 |

39 |

| 1½ |

48.3 |

57 |

29 |

114 |

47 |

| 2 |

60.3 |

76 |

35 |

152 |

63 |

| 2½ |

73 |

95 |

44 |

190 |

79 |

| 3 |

88.9 |

114 |

51 |

229 |

95 |

| 3½ |

101.6 |

133 |

57 |

267 |

111 |

| 4 |

114.3 |

152 |

64 |

305 |

127 |

| 5 |

141.3 |

190 |

79 |

381 |

157 |

| 6 |

168.3 |

229 |

95 |

457 |

189 |

| 8 |

219.1 |

305 |

127 |

610 |

252 |

| 10 |

273 |

381 |

159 |

762 |

316 |

| 12 |

323.8 |

457 |

190 |

914 |

378 |

| 14 |

355.6 |

533 |

222 |

1067 |

441 |

| 16 |

406.4 |

610 |

254 |

1219 |

505 |

| NPS |

O.D.

D |

90°

Long Rad

Center to End

A |

45°

Long Rad

Center to End

B |

90°

3D

Center to End

A |

45°

3D

Center to End

B |

| 18 |

457 |

686 |

286 |

1372 |

568 |

| 20 |

508 |

762 |

318 |

1524 |

632 |

| 22 |

559 |

838 |

343 |

1676 |

694 |

| 24 |

610 |

914 |

381 |

1829 |

757 |

| 26 |

660 |

991 |

406 |

1981 |

821 |

| 28 |

711 |

1067 |

438 |

2134 |

883 |

| 30 |

762 |

1143 |

470 |

2286 |

946 |

| 32 |

813 |

1219 |

502 |

2438 |

1010 |

| 34 |

864 |

1295 |

533 |

2591 |

1073 |

| 36 |

914 |

1372 |

565 |

2743 |

1135 |

| 38 |

965 |

1448 |

600 |

2896 |

1200 |

| 40 |

1016 |

1524 |

632 |

3048 |

1264 |

| 42 |

1067 |

1600 |

660 |

3200 |

1326 |

| 44 |

1118 |

1676 |

695 |

3353 |

1389 |

| 46 |

1168 |

1753 |

727 |

3505 |

1453 |

| 48 |

1219 |

1829 |

759 |

3658 |

1516 |

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) must be specified by customer.

Dimensional Tolerances of Buttweld Bend/Elbows - 45° and 90° - LR and 3D - ASME B16.9 -

| Nominal Pipe Size |

1/2 to 2½ |

3 to 3½ |

4 |

5 to 8 |

Outside Diameter

at Bevel (D) |

+ 1.6

- 0.8 |

1.6 |

1.6 |

+ 2.4

- 1.6 |

| Inside Diameter at End |

0.8 |

1.6 |

1.6 |

1.6 |

| Center to End LR (A/B) |

2 |

2 |

2 |

2 |

| Center to End 3D (A/B) |

3 |

3 |

3 |

3 |

| Nominal Pipe Size |

10 to 18 |

20 to 24 |

26 to 30 |

32 to 48 |

Outside Diameter

at Bevel (D) |

+ 4

- 3.2 |

+ 6.4

- 4.8 |

+ 6.4

- 4.8 |

+ 6.4

- 4.8 |

| Inside Diameter at End |

3.2 |

4.8 |

+ 6.4

- 4.8 |

+ 6.4

- 4.8 |

| Center to End LR (A/B) |

2 |

2 |

3 |

5 |

| Center to End 3D (A/B) |

3 |

3 |

6 |

6 |

| Wall Thickness (t) |

Not less than 87.5% of Nominal Wall Thickness |

Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

Note:

MSS SP-43 only covers stainless steel buttweld fittings made for use with Schedule 5S and 10S pipe and Stub Ends suitable for use with Schedule 40S pipe, as defined in ASME B36.19. The dimensions and dimensional tolerances defined in MSS SP-43 are substantially the same as those in ASME B16.9 specifications from NPS 1/2 - NPS 24. Except with regard to the outside diameter at the bevel.

ASME B16.9 Buttweld Long Redius Bend Specification:

Size : Seamless Pipe Bends (1/2″ – 24″), ERW / Welded / Fabricated Pipe Bends (2″ – 36″)

Standards : ASME / ANSI - B 16.9, ASTM A403 - ASME SA403, ASME B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

Thickness : 2-40 mm / SCh4, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated

Bending Radius : R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Form : Piggable Bend, Hot Bend, Long Radius Bend, Induction Bend

ASME B16.9 Buttweld Long Redius Bend Material & Grades :

Stainless Steel Buttweld Long Redius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Duplex & Super Duplex Steel Buttweld Long Redius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462

Carbon Steel Buttweld Long Redius Bend : ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel Buttweld Long Redius Bend : ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Nickel Alloy Buttweld Long Redius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

1d bend, 2d bend, 3d bend, 5d bend, 2d bend, 10d bend, 12d bend & Long radius bend manufacturer in India, Mumbai,UAE,Dubai,USA,UK

Call@ +91-9987994248. The prime global leader for 3d bend, 5d bend, 2d bend, 10d bend, 12d bend & long radius bend manufacturer in India & also supplier in Mumbai, Chennai, Pune, Uk & UAE. Buy Lond Radius Bend is ideal to use in the drainage pipe systems as their longer bodies help in cleaning the waste inside the pipe.

Other Names: Long Radius Bend, 5d bend, 2d bend, 10d bend, long radius bend

Material: Stainless Steel, Carbon Steel, Alloy Steel & High Nickel Grade

Brand: Fitwel Industries LLP

manufacturer: Fitwel Industries LLP

Suppliers & Exporter: Fitwel Industries LLP

Rating: 4.7/5 based on 1112 customer reviews

Buttweld Long Redius Bend Applications

Our products are of high quality and come with complete certification and marking on each fitting. We also provide a range of custom size industrial products to serve the growing needs of the industrial sector spanning fabricators, petrochemicals, sugar, edible oils, fertilizers, chemical, oil and gas, pharmaceuticals, pulp and paper manufacturing, power generation, and other engineering industries.

If you are Looking for Long Radius Bend, 5d bend, 2d bend, 10d bend Long Radius Bend manufacturer & Exporter, Supplier? We are manufacturers and Leading Suppliers of Long Radius Bend in India. Email Us Your Requirements for Best Quality Fittings Product at Competitive Prices!.

Long Radius Bend Manufacturer World Wide

Below, We are having existence in countries below for Long Radius Bend

-

Long Radius Bend Manufacturer in Dubai, UAE

We are the leading manufacturer and supplier of

Long Radius Bend in Dubai, United Arab Emirates. Get the best offer for high-quality

Long Radius Bend from us in UAE, Dunbai. We have plenty of stock of Long Radius Bend in the UAE. Place your order online for Long Radius Bend in Dubai, United Arab Emirates. We are the leading

Long Radius Bend manufacturer in Dubai, UAE. Get your best quality Long Radius Bend in Dubai. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Singapore

We are the leading manufacturer and supplier of

Long Radius Bend in Singapore. Get the best offer for high-quality Long Radius Bend from us in Singapore. We have plenty of stock of Long Radius Bend in the Singapore. Place your order online for Long Radius Bend in Singapore. We are the leading

Long Radius Bend manufacturer in Singapore. Get your best quality Long Radius Bend in Singapore. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Oman

We are the leading manufacturer and supplier of

Long Radius Bend in Oman. Get the best offer for high-quality Long Radius Bend from us in Oman. We have plenty of stock of Long Radius Bend in the Oman. Place your order online for Long Radius Bend in Oman. We are the leading

Long Radius Bend manufacturer in Oman. Get your best quality Long Radius Bend in Oman. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Italy

We are the leading manufacturer and supplier of

Long Radius Bend in Italy. Get the best offer for high-quality Long Radius Bend from us in Italy. We have plenty of stock of Long Radius Bend in the Italy. Place your order online for Long Radius Bend in Italy. We are the leading

Long Radius Bend manufacturer in Italy. Get your best quality Long Radius Bend in Italy. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Qatar

We are the leading manufacturer and supplier of

Long Radius Bend in Qatar. Get the best offer for high-quality Long Radius Bend from us in Qatar. We have plenty of stock of Long Radius Bend in the Qatar. Place your order online for Long Radius Bend in Qatar. We are the leading

Long Radius Bend manufacturer in Qatar. Get your best quality Long Radius Bend in Qatar. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Australia

We are the leading manufacturer and supplier of

Long Radius Bend in Australia. Get the best offer for high-quality Long Radius Bend from us in Australia. We have plenty of stock of Long Radius Bend in the Australia. Place your order online for Long Radius Bend in Australia. We are the leading

Long Radius Bend manufacturer in Australia. Get your best quality Long Radius Bend in Australia. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in New Zealand

We are the leading manufacturer and supplier of

Long Radius Bend in New zealand. Get the best offer for high-quality Long Radius Bend from us in New zealand. We have plenty of stock of Long Radius Bend in the New zealand. Place your order online for Long Radius Bend in New zealand. We are the leading

Long Radius Bend manufacturer in New zealand. Get your best quality Long Radius Bend in New zealand. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Saudi Arabia

We are the leading manufacturer and supplier of

Long Radius Bend in Saudi Arabia. Get the best offer for high-quality Long Radius Bend from us in Saudi Arabia. We have plenty of stock of Long Radius Bend in the Saudi Arabia. Place your order online for Long Radius Bend in Saudi Arabia. We are the leading

Long Radius Bend manufacturer in Saudi Arabia. Get your best quality Long Radius Bend in Saudi Arabia. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Bahrain

We are the leading manufacturer and supplier of

Long Radius Bend in Bahrain. Get the best offer for high-quality Long Radius Bend from us in Bahrain. We have plenty of stock of Long Radius Bend in the Bahrain. Place your order online for Long Radius Bend in Bahrain. We are the leading

Long Radius Bend manufacturer in Bahrain. Get your best quality Long Radius Bend in Bahrain. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in UK

We are the leading manufacturer and supplier of

Long Radius Bend in UK. Get the best offer for high-quality Long Radius Bend from us in UK. We have plenty of stock of Long Radius Bend in the UK. Place your order online for Long Radius Bend in UK. We are the leading

Long Radius Bend manufacturer in UK. Get your best quality Long Radius Bend in UK. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Austria

We are the leading manufacturer and supplier of

Long Radius Bend in Austria. Get the best offer for high-quality Long Radius Bend from us in Austria. We have plenty of stock of Long Radius Bend in the Austria. Place your order online for Long Radius Bend in Austria. We are the leading

Long Radius Bend manufacturer in Austria. Get your best quality Long Radius Bend in Austria. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Nigeria

We are the leading manufacturer and supplier of

Long Radius Bend in Nigeria. Get the best offer for high-quality Long Radius Bend from us in Nigeria. We have plenty of stock of Long Radius Bend in the Nigeria. Place your order online for Long Radius Bend in Nigeria. We are the leading

Long Radius Bend manufacturer in Nigeria. Get your best quality Long Radius Bend in Nigeria. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Sudan

We are the leading manufacturer and supplier of

Long Radius Bend in Sudan. Get the best offer for high-quality Long Radius Bend from us in Sudan. We have plenty of stock of Long Radius Bend in the Sudan. Place your order online for Long Radius Bend in Sudan. We are the leading

Long Radius Bend manufacturer in Sudan. Get your best quality Long Radius Bend in Sudan. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Egypt

We are the leading manufacturer and supplier of

Long Radius Bend in Egypt. Get the best offer for high-quality Long Radius Bend from us in Egypt. We have plenty of stock of Long Radius Bend in the Egypt. Place your order online for Long Radius Bend in Egypt. We are the leading

Long Radius Bend manufacturer in Egypt. Get your best quality Long Radius Bend in Egypt. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Zambia

We are the leading manufacturer and supplier of

Long Radius Bend in Zambia. Get the best offer for high-quality Long Radius Bend from us in Zambia. We have plenty of stock of Long Radius Bend in the Zambia. Place your order online for Long Radius Bend in Zambia. We are the leading

Long Radius Bend manufacturer in Zambia. Get your best quality Long Radius Bend in Zambia. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Libya

We are the leading manufacturer and supplier of

Long Radius Bend in Libya. Get the best offer for high-quality Long Radius Bend from us in Libya. We have plenty of stock of Long Radius Bend in the Libya. Place your order online for Long Radius Bend in Libya. We are the leading

Long Radius Bend manufacturer in Libya. Get your best quality Long Radius Bend in Libya. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Brazil

We are the leading manufacturer and supplier of

Long Radius Bend in Brazil. Get the best offer for high-quality Long Radius Bend from us in Brazil. We have plenty of stock of Long Radius Bend in the Brazil. Place your order online for Long Radius Bend in Brazil. We are the leading

Long Radius Bend manufacturer in Brazil. Get your best quality Long Radius Bend in Brazil. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Chile

We are the leading manufacturer and supplier of

Long Radius Bend in Chile. Get the best offer for high-quality Long Radius Bend from us in Chile. We have plenty of stock of Long Radius Bend in the Chile. Place your order online for Long Radius Bend in Chile. We are the leading

Long Radius Bend manufacturer in Chile. Get your best quality Long Radius Bend in Chile. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in USA

We are the leading manufacturer and supplier of

Long Radius Bend in USA. Get the best offer for high-quality Long Radius Bend from us in USA. We have plenty of stock of Long Radius Bend in the USA. Place your order online for Long Radius Bend in USA. We are the leading

Long Radius Bend manufacturer in USA. Get your best quality Long Radius Bend in USA. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Mexico

We are the leading manufacturer and supplier of

Long Radius Bend in Mexico. Get the best offer for high-quality Long Radius Bend from us in Mexico. We have plenty of stock of Long Radius Bend in the Mexico. Place your order online for Long Radius Bend in Mexico. We are the leading

Long Radius Bend manufacturer in Mexico. Get your best quality Long Radius Bend in Mexico. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Denmark

We are the leading manufacturer and supplier of

Long Radius Bend in Denmark. Get the best offer for high-quality Long Radius Bend from us in Denmark. We have plenty of stock of Long Radius Bend in the Denmark. Place your order online for Long Radius Bend in Denmark. We are the leading

Long Radius Bend manufacturer in Denmark. Get your best quality Long Radius Bend in Denmark. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Ukraine

We are the leading manufacturer and supplier of

Long Radius Bend in Ukraine. Get the best offer for high-quality Long Radius Bend from us in Ukraine. We have plenty of stock of Long Radius Bend in the Ukraine. Place your order online for Long Radius Bend in Ukraine. We are the leading

Long Radius Bend manufacturer in Ukraine. Get your best quality Long Radius Bend in Ukraine. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Peru

We are the leading manufacturer and supplier of

Long Radius Bend in Peru. Get the best offer for high-quality Long Radius Bend from us in Peru. We have plenty of stock of Long Radius Bend in the Peru. Place your order online for Long Radius Bend in Peru. We are the leading

Long Radius Bend manufacturer in Peru. Get your best quality Long Radius Bend in Peru. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Lebanon

We are the leading manufacturer and supplier of

Long Radius Bend in Lebanon. Get the best offer for high-quality Long Radius Bend from us in Lebanon. We have plenty of stock of Long Radius Bend in the Lebanon. Place your order online for Long Radius Bend in Lebanon. We are the leading

Long Radius Bend manufacturer in Lebanon. Get your best quality Long Radius Bend in Lebanon. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Russia

We are the leading manufacturer and supplier of

Long Radius Bend in Russia. Get the best offer for high-quality Long Radius Bend from us in Russia. We have plenty of stock of Long Radius Bend in the Russia. Place your order online for Long Radius Bend in Russia. We are the leading

Long Radius Bend manufacturer in Russia. Get your best quality Long Radius Bend in Russia. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in France

We are the leading manufacturer and supplier of

Long Radius Bend in France. Get the best offer for high-quality Long Radius Bend from us in France. We have plenty of stock of Long Radius Bend in the France. Place your order online for Long Radius Bend in France. We are the leading

Long Radius Bend manufacturer in France. Get your best quality Long Radius Bend in France. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Hungary

We are the leading manufacturer and supplier of

Long Radius Bend in Hungary. Get the best offer for high-quality Long Radius Bend from us in Hungary. We have plenty of stock of Long Radius Bend in the Hungary. Place your order online for Long Radius Bend in Hungary. We are the leading

Long Radius Bend manufacturer in Hungary. Get your best quality Long Radius Bend in Hungary. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Ethiopia

We are the leading manufacturer and supplier of

Long Radius Bend in Ethiopia. Get the best offer for high-quality Long Radius Bend from us in Ethiopia. We have plenty of stock of Long Radius Bend in the Ethiopia. Place your order online for Long Radius Bend in Ethiopia. We are the leading

Long Radius Bend manufacturer in Ethiopia. Get your best quality Long Radius Bend in Ethiopia. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Uganda

We are the leading manufacturer and supplier of

Long Radius Bend in Uganda. Get the best offer for high-quality Long Radius Bend from us in Uganda. We have plenty of stock of Long Radius Bend in the Uganda. Place your order online for Long Radius Bend in Uganda. We are the leading

Long Radius Bend manufacturer in Uganda. Get your best quality Long Radius Bend in Uganda. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in South Africa

We are the leading manufacturer and supplier of

Long Radius Bend in South Africa. Get the best offer for high-quality Long Radius Bend from us in South Africa. We have plenty of stock of Long Radius Bend in the South Africa. Place your order online for Long Radius Bend in South Africa. We are the leading

Long Radius Bend manufacturer in South Africa. Get your best quality Long Radius Bend in South Africa. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

- Duplex Steel Long Radius Bend : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Worst-off No. 1.4462

- Nickel Alloy Long Radius Bend : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

-

Long Radius Bend Manufacturer in Argentina

We are the leading manufacturer and supplier of

Long Radius Bend in Argentina. Get the best offer for high-quality Long Radius Bend from us in Argentina. We have plenty of stock of Long Radius Bend in the Argentina. Place your order online for Long Radius Bend in Argentina. We are the leading

Long Radius Bend manufacturer in Argentina. Get your best quality Long Radius Bend in Argentina. Our Long Radius Pipe Bends Buttweld Pipe Fittings are manufactures with dissimilar grades of standard ranges and meets its provisions through international and national standards.

What is a Long Radius Bend?

A long radius bend is ideal to use in the daring pipe system as their longer bodies help in cleansing the west inside the pipe and controlling the formation of clogs. Long radius bend that is 1.5 times bigger than the normal diameters of the pipes. Easy to fit our ANSI B16.9 long radius bend promotes flexibility sufficient enough for expending and decreasing the pipeline, ASME B16.9 long radius bend made of Inconel gives oxidation resistance and resistance to befouling.

Standard: ANSI/ASME, MSS, JIS, DIN, BS, etc.

Grade of Long Radius Bend

- Stainless Steel Long Radius Bend : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

- Carbon Steel Long Radius Bend: ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

- Low Temperature Carbon Steel Long Radius Bend: ASTM A420 WPL3, A420 WPL6

- Alloy Steel Long Radius Bend: ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91