Fitwel Industries LLP is recognized name as a flanges manufacturer in India, using modern engineering flanges manufacturing process of different shapes, sizes, specifications, pressure ratings, and standards as per the customers’ requirements. We are the world's prominent leader in Forged Flanges & Socket Weld Flanges. We cater to the huge global demand of our customers who are spread across all over countries & cities.

The International Industrial Flanges Manufacturers in India, also suppliers of flanges in grades namely Stainless steel flanges, Carbon steel Flanges, Alloy steel Flanges, Low-Temperature Carbon Steel Flanges, High Yield Carbon Steel Flanges, High Nickel Alloy Flanges, Monel Flanges, Hastelloy Flanges, Nickel Flanges, Alloy 20 Flanges, Inconel Flanges, Titanium Flanges etc. Rather than flanges, we do also manufacture big-sized ring flanges, customized ring flanges from Rolled Plates, Forgings & Plates, also big diameter flanges as per the customer's requirement, convenience & drawing.

Our Flanges division encompasses an integrated forge shop that manufactures all types of pipe fittings & Flanges in various specifications i.e. ASME/ ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, UNI, etc. We produced either Forged Flanges Manufacturer in India Or Plate Flanges Manufacturer in India for industrial usage in the size range from ½” to 40”. Higher capability range, exceptional quality, and unrivaled clients' satisfactory service make us a very premium value solution for all of your flanges' needs.

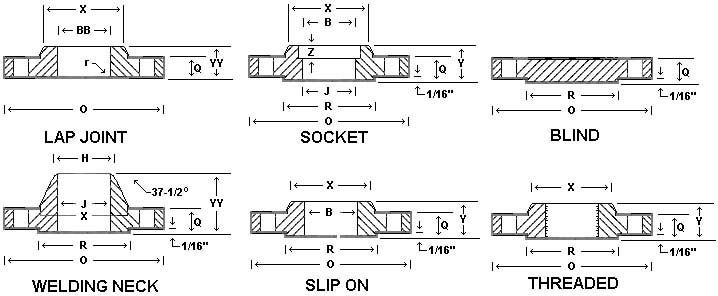

We are being in the Flanges & Fittings business for more than three decades, Fitwel Industries LLP evolving ourselves with time, we have secured a special space for ourselves within the industry as well as among our customers in the domestic as well as international markets which also is a core part of our USP. Our way of management style has been the key to our success as we delegate responsibility to the specific needs of every customer and we have made every customer a member of our family organization. We are the major primium manufacturer of all types of flanges such as Slip-on Flanges, BLRF Flanges, Weldneck Flanges, Socket Weld Flanges, Ring Joint Flanges, Long Weld Neck Flanges, Plate Flanges, Threaded Flanges, Raised Face Flanges, Large Diameter Flanges, Lap Joint Flanges, Orifice Flanges, Spacer Flanges and so on.

Flanges Manufacturers India is a forged or cast ring of steel designed to connect mechanically sections of pipe or join pipe to a pump, valve, pressure vessel or any other piece of equipment. Stainless Steel Flanges, Carbon Steel Flanges & Alloy Steel Flanges provide easy access for modification, cleaning or inspection. They usually come in various shapes, Pressure Rating, Weight Chart, Dimensions, size, grades & specification with ANSI/ ASME, EN, BS, DIN standards. The Flanges are joined to each other by bolting and joined to the piping system by threading or welding and are designed to the specific pressure ratings; 150lb, 300lb, 400lb, 600lb, 900lb, 1500lb and 2500lb.

Fitwel Industries LLP is highly acclaimed Flanges Manufacturer in Mumbai, as well as surely a reputed and well-known brand in the global & Indian metal market for its reliability and quality. We treat our clients as our partners by providing them with our products and service & solutions. And this ethos is displayed in not only our thoughts but also in our works. We have world-class ultra-modern manufacturing facilities for forgings and Flanges. Our range of Industrial Flanges Manufacturers in Mumbai is ideal for application in diverse industries for high pressure and temperature applications.

A Flanges is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two Flanges with a gasket between them to provide a seal.

Materials for Flanges. Pipe flanges are manufactured in all the different materials like stainless steel, cast iron, aluminium, brass, bronze, plastic etc. but the most used material is forged carbon steel and have machined surfaces.

The most common materials for pipe flanges (forged grades) are: ASTM A105 (carbon steel high temperature to match A53/A106/API 5L pipes), A350 Grades LF1/2/3 (carbon steel low temperature to match A333 pipes), A694 Grades F42 to F80 (high yield carbon steel to match API 5L pipe grades), ASTM A182 Grades F5 to F91.

A flange standard lays down the dimensions, surface finish, facing type, marking, material and technical specifications for flanges. National flange standards in Europe have largely been superseded by the European EN 1092 series.

Standard Flange Classification: The most common flanges pressure classes are #150, #300, #600, #900, #1500, #2500 and #3000 according to ASME designation. To other standards, as DIN, pressure classes are defined by the acronym PN, as for example, PN10, PN16, PN20, PN25, PN40, PN50, PN100, PN150, PN250 or PN420.

For example, a Class 150 flange is rated to approximately 270 PSIG at ambient conditions, 180 PSIG at approximately 400°F, 150 PSIG at approximately 600°F, and 75 PSIG at approximately 800°F. In other words, when the pressure goes down, the temperature goes up and vice versa.

Offering a reliable way to connect pipe systems with the various equipment, valves, and other components of virtually any processing system, flanges are the second most used joining method after welding. Using flanges adds flexibility when maintaining piping systems by allowing for easier disassembly and improved access to system components.

A typical flanged connection is comprised of three parts:

In most cases, there are specific gasket and bolting materials made from the same, or approved materials as the piping components you wish to connect. Stainless Steel flanges are some of the most common. However, flanges are available in a wide range of materials so matching them with your needs is essential.

Other common flange materials include Monel, Inconel, Chrome Moly, and many others depending on the application.

The best option for your needs will depend on both the system in which you intend to use the flange and your specific requirements.

Flanges are not a one-type-fits-all sort of solution. Sizing aside, matching the ideal flange design to your piping system and intended usage will help to ensure reliable operation, a long service life, and optimal pricing.

Here’s a look at the most common flange types available.

Also known as a screwed flange, this style has a thread inside the flange bore which fits with the matching male thread on the pipe or fitting. The threaded connection means you can avoid welding in many use cases. Simply match the threading to the pipes you wish to connect.

Ideal for smaller pipe diameters in low-temperature and low-pressure scenarios, socket-weld flanges feature a connection in which you place the pipe into the flange and then secure the connection with a single multi-pass fillet weld. This makes this style simpler to install than other welded flange types while avoiding the limitations associated with threaded ends.

Slip-on flanges are very common and are available in a large range of sizes to accommodate systems with higher flow rates and throughput. Simply match the flange to the outer diameter of the pipe you intend to connect. Installation is slightly more technical as you’ll need fillet weld both sides to secure the flange to the pipe.

Featuring a two-piece design, lap joint flanges require butt welding of the stub end to the pipe or fitting with the use of a backing flange to create the flanged connection. This design makes this style popular for use in systems with limited physical space or systems which require frequent dismantling and maintenance.

Like lap joint flanges, weld neck flanges require butt welding for installation. However, their integrity, performance in systems with multiple repeat bends, and the ability to use them in high-pressure and high-temperature systems make them a leading choice for process piping.

Used for terminating or isolating piping systems, blind flanges are essentially boltable blank discs. When installed properly and combined with the correct gaskets, they can achieve an outstanding seal which is easy to remove when needed.

The flange types listed above are the most common. However, there is a range of additional specialized flange types available to suit a range of uses and environments. Other options include nipoflanges, weldoflanges, expanding flanges, orifice, long weld neck and reducing flanges.

Flange design is only the start when considering the ideal flange for your piping system. Face types are another characteristic that will have a major impact on the final performance and service life of your flanges.

Facing types determine both the gaskets needed to install the flange and characteristics related to the seal created.

Flat Face (FF): As the name suggests, flat face flanges feature a flat, even surface combined with a full face gasket that contacts most of the flange surface.

Raised Face (RF): These flanges feature a small raised section around the bore with an inside bore circle gasket.

Ring Joint Face (RTJ): Used in high-pressure and high-temperature processes, this face type features a groove in which a metal gasket sits to maintain the seal.

Tongue and Groove (T&G): These flanges feature matching grooves and raised sections. This aids in installation as the design helps the flanges to self-align and provides a reservoir for gasket adhesive.

Male & Female (M&F): Similar to tongue and groove flanges, these flanges use a matching pair of grooves and raised sections to secure the gasket. However, unlike tongue and groove flanges, these retain the gasket on the female face, providing more accurate placement and increased gasket material options.

Many face types also offer one of two finishes: serrated or smooth.

Choosing between the options is important as they will determine the optimal gasket for a reliable seal.

In general, smooth faces work best with metallic gaskets while serrated faces help to create stronger seals with soft material gaskets.

Apart from the functional design of a flange, flange dimensions are the most likely factor to impact flange choices when designing, maintaining, or updating a piping system.

However, you must consider how the flange interfaces with the pipe and the gaskets in use to ensure proper sizing.

Each of the above characteristics will have an influence on how the flange performs across a range of processes and environments.

So how can you tell which flanges are up to the task and which are not?

Flanges are often classified based on their ability to withstand temperatures and pressures.

This is designated using a number and either the “#”, “lb”, or “class” suffix. These suffixes are interchangeable but will differ based on the region or vendor.

Exact pressure and temperature tolerances will vary by materials used, flange design, and flange size. The only constant is that in all cases, pressure ratings decrease as temperatures rise.

To help make comparison easier, flanges fall under global standards established by the American Society of Mechanical Engineers (ASME) — ASME B16.5 & B16.47.

If you’re attempting to replace or verify existing parts, all flanges must include markers — typically on their outer perimeter — to aid in the process.

Special designations, if any — for example, QT for Quenched and tempered or W for repair by welding This guide offers a solid foundation of the basics of flange design and how to choose the ideal flange for your piping system. However, with a wide range of stainless steel flanges and other flange materials available, it is impossible to list every configuration, detail, or consideration.

We manufacture flanges according to various Specifications. The complete specifications and size range are given below.

| Flanges Size | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flanges Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Flanges |

| Flanges Pressure in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Flanges |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Flanges |

| Flanges Manufacturing Method | Forged / Threaded / Screwed / Plate |

| Flanges Manufacturer in India | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Flanges Application |

|

| Material Forms | Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex Steel, Titanium, Hastelloy, High Nickel Alloy, etc. |

| Test Certificates |

EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| JIS Flanges | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Flanges |

| UNI Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Flanges |

| EN Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Flanges |

| Connect Type/ Flanges Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Flanges Special design |

As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2") to 200 NB (8") Equal & Reducing Configurations |

| Type Of Test | Direct-reading Spectrograph, Hydrostatic Testing Machine, X-ray Detector, Ultrasonic Flaw Detector, Magnetic Particle Detector |

| Equipment Used | Press Machine, Bending Machine, Pushing Machine, Electric Bevelling Machine, Sand-Blasting Machine, etc. |

| Country Origin | Indian / West Europe / Japan / USA / Korean |

| ASME/ANSI B 16.5 | Weld Neck Flange, Slip on Flange, Blind Flange, High Hub Blind, Socket Weld, Lap Joint, Threaded Flange, Ring Type Joint |

|---|---|

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Weld Neck, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Weld Neck, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Weld Neck, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate, Loose Plate, Loose Plate With Weld Neck , Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Weld Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Weld Neck Flange, Socket Weld Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Weld Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN Flanges | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

The following shall be included in the purchase description for flanges:

| Flanges Class 150 | Flanges Threaded |

| Flanges Class 300 | Flanges With 1/2 Npt |

| Flanges Class 1500 | Flanges With Threaded Hole |

| Flanges Class 600 | Flanges Weight 150# |

| Flanges Class 900 | Flanges Rtj 1500 |

| Flanges Class 2500 | Flanges Ring Type Joint |

| Flanges Pn16 | Flanges Flat Face |

| Flanges Pn10 | Flanges Slip On |

| Flanges Pn40 | Flanges Rtj 900 |

| Flanges Pn 160 | Flanges Rtj |

| Flanges Pn 64 | Flanges Npt |

| Flanges Dn150 Pn16 | Flanges Jis 5k |

| Flanges Din 2527 | Flanges Jis B2220 |

| Flanges Din En 1092-1 | Flanges Jis 10k |

| Flanges Din 2633 | Kf Flanges |

| Flanges Din 2576 | Flanges B16.47 |

| Flanges Asme B16.5 Class 300 | Flanges Ansi B16.5 150 |

Prices for SS Flanges Products are very affordable.

Please Call Or Email us on 9987994248 Or sales@fitwelindia.com to request the updated price list and ready stock information along with your requirement. Fitwel Industries LLP maintains a stock of all standard items and can export them at the best price ASME SA 182 Stainless Steel Flanges, Slip on Flanges, Weld Neck Flanges, Socket weld Flanges, Threaded, Lap Joint Flanges, RTJ Flanges etc.