Based in India, Fitwel Industries LLP is the leading global manufacturer and suppliers of buttweld pipe fittings and flanges. The most common dimensional standard for buttweld pipe fittings is SME B16.9, B16.28 MSS-SP43/75 for sizes ranging from ½& to 72 (in all Schedules). In addition to standard size buttweld fittings, we can also offer larger sizes on customer request. We specialize in the manufacture of a wide variety of buttweld pipe fittings including elbows, bends, tees, crosses, reducers, caps and more. Our continuing commitment to the production of quality products has made us the most preferred choice in various industries such as power generation, petroleum, natural gas, chemical, shipbuilding, heating, papermaking, metallurgy, among others.

A Ped Certified Buttweld Fitting is a part which is joined to a Buttweld. An American standard Buttweld thread is a type of screw or thread, commonly used on Buttweld fittings to assure a tight seal. A Buttweld fitting is a part which is joined to a Buttweld. These are used to combine, divert or reduce the flow of the water supply, and they come in a variety of sizes to fit the Buttweld they will connect.

Ped Approved Buttweld Fittings dimensions are important and there are sizing standards to follow. While most have openings of the same size on each end, some fittings are designed with different-sized openings and serve as the transition from one size Buttweld to another. Buttweld Fittings are Piping component that helps in Changes the direction of the flow such as elbows, tees. Changes the size of the Buttweld such as reducers, reducing tees. Connect different components such as couplings and stop the flows such as Caps.

A pipe fitting is defined as a part used in a piping system, for changing direction, branching or for change of pipe diameter, and which is mechanically joined to the system.

There are many different types of fittings and they are the same in all sizes and schedules as the pipe.

Fittings are divided into three groups:-

Buttweld fittings manufacturer in India, also known as Buttweld connectors, attach one Buttweld to another in order to lengthen the run or change the flow direction in a plumbing system. These are used to combine, divert or reduce the flow of the water supply, and they come in a variety of sizes to fit the Buttweld they will connect.

The basic purpose of using Buttweld fittings in Buttweld systems is to connect the bores of two or more Buttwelds or tubes. Buttweld fittings are used in piping systems normally :-

They are also used to close or seal a Buttweld.

Buttweld fittings are generally classified as "welded" or "pressure" fittings. Welded fittings are welded on to the piping system where as pressure fitting uses National Buttweld Thread (NPT) to connect to the Buttweld. Pressure fittings are classified as 3000#, 6000# or 9000# (most common).

Buttweld fittings are usually manufactured from the Buttweld, bar, hollow bar, castings, or forgings. The fittings are used in non-critical, low-pressure applications where welding is not possible or required. They, therefore, provide a relatively low-cost method of connection. Buttweld Fittings Manufacturers India are usually fitted with a sealant (paste or tape such as PTFE) and are considered to be permanent Buttweld-work. Buttweld or socket weld fittings are a type of fittings used for forming circumferential butt weld joints in Buttweldwork systems. They are used for critical systems and in areas where Buttweld-work is permanent and are designed to provide good flow characteristics.

Fittings for piping systems can be expensive and require a proportionally large labor element to install, therefore correct selection and use is of vital importance to a well-installed piping system. Every type of piping material has a range of fittings that can be used with it and some piping materials can have multiple different ranges of fittings that can be used. For example, copper piping systems can be installed by bending the Buttweld and therefore using no elbows, using soldered copper fittings or compression brass fittings depending on the type of service being transferred in the copper Buttweld. Fittings are generally available with ends to match the piping installation.

Fittings for Buttweld and tubing are most often made from the same base material as the Buttweld or tubing being connected, e.g., stainless steel, steel, copper, or plastic. However, any material that is allowed by code may be used but must be compatible with the other materials in the system, the fluids being transported, and the temperatures and pressures inside and outside of the system.

The material with which a Buttweld is manufactured often forms the basis for choosing Buttweld fittings. Buttweld fittings are made of the following materials.

-normally used for high-temperature service

While there are thousands of specialized Buttweld fittings manufacturers Ahmedabad, some common types of Buttweld fittings which are used widely in piping systems are- (i) elbow, (ii) tee, (iii) cross, (iv) reducer, (v) cap or plug, (vi) union, (vii) coupling, (viii) nipple, etc.

Buttweld fittings are most commonly available in carbon steel, stainless steel, nickel alloy, aluminum, and high yield material. High yield butt weld carbon steel Buttweld fittings are available in A234-WPB, A234-WPC, A420-WPL6, Y-52, Y-60, Y-65, Y-70. All WPL6 Buttweld fittings are annealed and are NACE MR0157 and NACE MR0103 compatible.

Common Materials for Welded Buttweld Fittings:-

A234 WPB is the most common material used for carbon steel butt welded fittings.

ASTM A234 WPB is the Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

|

Grade |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

Ni |

Cu |

Others |

|

– |

– |

– |

max |

max |

– |

– |

– |

– |

– |

– |

|

WPB |

0.3 |

0.29-1.06 |

0.05 |

0.058 |

0.1 |

0.4 |

0.15 |

0.4 |

0.4 |

V 0.08 |

|

(1,2,3,4,5) |

max |

– |

– |

– |

min |

max |

max |

max |

max |

max |

Stainless buttweld fittings are available in 316 and 304 grades.

|

C |

Cr |

Mn |

Ni |

P |

S |

Si |

|

MAX |

– |

MAX |

– |

MAX |

MAX |

MAX |

|

0.035 |

18.0- 20.0 |

2.00 |

8.0-13.0 |

0.045 |

0.030 |

1.00 |

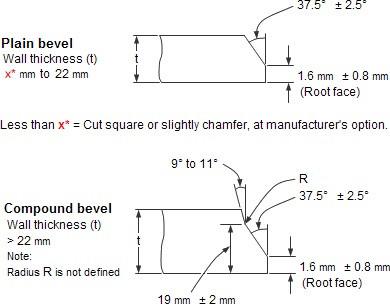

All welded pipe fittings have bevelled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases.

There are two types of bevels;-

Welded pipe fittings are made as per ASME spec B16.9. ASME B16.9 covers factory made wrought steel butwelding fittings in sizes 1/2" to 48". This standard however does not cover low pressure corrosion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-Welding Fittings.

All butt weld fittings have beveled ends as per ASME B16.25 standard. This helps create full penetration weld without any extra preparation needed for the butt weld fitting.