We are Renowned Exporter, and Supplier of Buttweld Fittings Manufacturer in Ukraine. Buttweld Fittings are designed and developed in accordance with the International Quality Standards. We also customize buttweld Pipe Fitting as per the purchasers requirements in Ukraine. Our clients satisfaction depends on things like quality, hardness, delivery time, fast response and our service for Buttweld Fittings.

We are a Buttweld Fittings Supplier in Ukraine with extensive production capacity for supply of buttweld Elbow, buttweld Tee, buttweld Stub End, buttweld Reducer, buttweld Cap, buttweld Swage Nipple. Our production size range for SS buttweld Fittings, carbon steel buttweld Fittings is from 1/2”-24” for seamless construction and 18”-120” for welded construction in Ukraine. We are specialized in offering a large range of fine quality Buttweld Fittings within the grade stainless steel 304, 304L, 316, 316L, 321, 321H, 317, 317L, 441, 446, and 904L in Ukraine. These buttweld Fittings products are specially designed with compliance to the international standards using high grade materials.

We are one of the best Buttweld Fittings Manufacturer in Ukraine. We are most trusted Exporter and Supplier of SS Buttweld Fittings Manufacturer in Ukraine. We keep stock of Carbon Steel buttweld Fittings to fulfill urgent requirement of our clients at reasonable price in Ukraine. We are committed to on-time delivery of ANSI B 16.9 Buttweld Fittings Manufacturer in Ukraine. We supply a high quality Alloy Steel Buttweld Fittings Manufacturer in Ukraine.

Leading Suppliers & Manufacturer and Exporters of Stainless Steel Buttweld Fittings, Carbon Steel, Alloy Steel, Inconel, Monel, Hastelloy, Nickel Alloys, Duplex, Super Duplex, Titanium, Alloy 20, 254 SMO Buttweld Fittings at market leading Best prices in Ukraine.

A Buttweld fitting is a part which is joined to a Buttweld. An American standard Buttweld thread is a type of screw or thread, commonly used on Buttweld fittings to assure a tight seal. A Buttweld fitting is a part which is joined to a Buttweld. These are used to combine, divert or reduce the flow of the water supply, and they come in a variety of sizes to fit the Buttweld they will connect.

Buttweld fittings dimensions are important and there are sizing standards to follow. While most have openings of the same size on each end, some fittings are designed with different-sized openings and serve as the transition from one size Buttweld to another. Buttweld Fittings are Piping component that helps in Changes the direction of the flow such as elbows, tees. Changes the size of the Buttweld such as reducers, reducing tees. Connect different components such as couplings and stop the flows such as Caps.

Buttweld Fittings Manufacturer , also known as Buttweld connectors, attach one Buttweld to another in order to lengthen the run or change the flow direction in a plumbing system. These are used to combine, divert or reduce the flow of the water supply, and they come in a variety of sizes to fit the Buttweld they will connect.

The basic purpose of using Buttweld Fittings Manufacturer in Buttweld systems is to connect the bores of two or more Buttwelds or tubes. Buttweld fittings are used in piping systems normally :-

They are also used to close or seal a Buttweld.

Buttweld fittings are generally classified as "welded" or "pressure" fittings. Welded fittings are welded on to the piping system where as pressure fitting uses National Buttweld Thread (NPT) to connect to the Buttweld. Pressure fittings are classified as 3000#, 6000# or 9000# (most common).

Buttweld fittings are usually manufactured from the Buttweld, bar, hollow bar, castings, or forgings. The fittings are used in non-critical, low-pressure applications where welding is not possible or required. They, therefore, provide a relatively low-cost method of connection. Buttweld Fittings Manufacturer Ukraine are usually fitted with a sealant (paste or tape such as PTFE) and are considered to be permanent Buttweld-work. Buttweld or socket weld fittings are a type of fittings used for forming circumferential butt weld joints in Buttweldwork systems. They are used for critical systems and in areas where Buttweld-work is permanent and are designed to provide good flow characteristics.

Fittings for piping systems can be expensive and require a proportionally large labor element to install, therefore correct selection and use is of vital importance to a well-installed piping system. Every type of piping material has a range of fittings that can be used with it and some piping materials can have multiple different ranges of fittings that can be used. For example, copper piping systems can be installed by bending the Buttweld and therefore using no elbows, using soldered copper fittings or compression brass fittings depending on the type of service being transferred in the copper Buttweld. Fittings are generally available with ends to match the piping installation.

Fittings for Buttweld and tubing are most often made from the same base material as the Buttweld or tubing being connected, e.g., stainless steel, steel, copper, or plastic. However, any material that is allowed by code may be used but must be compatible with the other materials in the system, the fluids being transported, and the temperatures and pressures inside and outside of the system.

The material with which a Buttweld is manufactured often forms the basis for choosing Buttweld fittings. Buttweld fittings are made of the following materials.

-normally used for high-temperature service

The bodies of fittings for Buttweld and tubing are most often of the same base material as the Buttweld or tubing being connected. However, any material that is allowed by the code may be used but must be compatible with the other materials in the system, the fluids being transported, and the temperatures and pressures inside and outside of the piping system. Fire hazards, earthquake resistance, and other factors also influence the choice of Buttweld fitting materials.

Hydraulic systems use extremely high fluid pressures to create useful work, such as in the hydraulic actuators for hydraulic-powered machinery. Therefore, hydraulic fittings are designed and rated for much greater pressures than those experienced in general piping systems, and they are generally not compatible for general use. Hydraulic fittings are designed and constructed to resist high-pressure leakage and sudden explosive failure.

While there are thousands of specialized Buttweld Fittings Manufacturer Ahmedabad, some common types of Buttweld fittings which are used widely in piping systems are- (i) elbow, (ii) tee, (iii) cross, (iv) reducer, (v) cap or plug, (vi) union, (vii) coupling, (viii) nipple, etc.

Buttweld fittings are to be selected considering certain factors. These factors are given below.

Buttweld fittings such as carbon steel and stainless steel offer many advantages compared to threaded and socket weld fittings. The latter is only available up to 4-inch nominal size whereas butt weld fittings are available in sizes from ½” to 72”.

Some of the advantages of weld fittings are;-

Buttweld fittings are most commonly available in carbon steel, stainless steel, nickel alloy, aluminum, and high yield material. High yield butt weld carbon steel Buttweld fittings are available in A234-WPB, A234-WPC, A420-WPL6, Y-52, Y-60, Y-65, Y-70. All WPL6 Buttweld fittings are annealed and are NACE MR0157 and NACE MR0103 compatible.

Common Materials for Welded Buttweld Fittings:-

A234 WPB is the most common material used for carbon steel butt welded fittings.

ASTM A234 WPB is the Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

|

Grade |

C |

Mn |

P |

S |

Si |

Cr |

Mo |

Ni |

Cu |

Others |

|

– |

– |

– |

max |

max |

– |

– |

– |

– |

– |

– |

|

WPB |

0.3 |

0.29-1.06 |

0.05 |

0.058 |

0.1 |

0.4 |

0.15 |

0.4 |

0.4 |

V 0.08 |

|

(1,2,3,4,5) |

max |

– |

– |

– |

min |

max |

max |

max |

max |

max |

Stainless buttweld fittings are available in 316 and 304 grades.

|

C |

Cr |

Mn |

Ni |

P |

S |

Si |

|

MAX |

– |

MAX |

– |

MAX |

MAX |

MAX |

|

0.035 |

18.0- 20.0 |

2.00 |

8.0-13.0 |

0.045 |

0.030 |

1.00 |

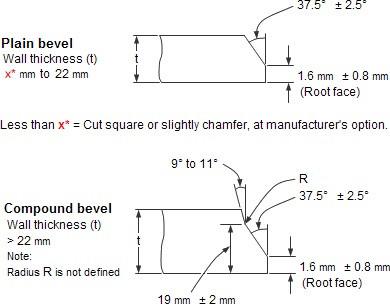

All welded pipe fittings have bevelled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases.

There are two types of bevels;-

Welded pipe fittings are made as per ASME spec B16.9. ASME B16.9 covers factory made wrought steel butwelding fittings in sizes 1/2" to 48". This standard however does not cover low pressure corrosion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-Welding Fittings.

A butt weld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of butt weld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dyes. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties. Read the link here to get more in depth detail of butt weld fitting manufacturing.

You will often hear SR45 elbow or LR45 elbow. The 45 or 90 refers to the angle of the bend for butt weld fitting to change the direction of flow. A long radius elbow (LR 90 Elbow or LR 45 elbow) will have a pipe bend that will be 1.5 times the size of the pipe. So, a 6 inch LR 90 has bending radius that is 1.5 x nominal pipe size. A short radius elbow (SR45 or SR90) has pipe bend that is equal to the size of fitting so a 6” SR 45 has bending radius that is 6” nominal pipe size.

One of The Largest Suppliers & Manufacturer, Exporters of ANSI/ASME B16.9 buttweld Fittings – Elbow, Tee, Reducer, Bend, Cross, End Caps, Stub End, Lap Joint Stub End, Collar, Swage Nipple at Competitive prices in Ukraine.

| Outside Diameter (OD) | 1/8” NB TO 48” NB. (Seamless & 100% X-Ray Welded, Fabricated) |

|---|---|

| Dimensions | ASME/ANSI B16.9, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313, ASME B16.28 |

| Type | Seamless / Welded / Fabricated – Elbow, Tee, Cross, Reducer, Nipple, Pipe Cap, Stubend, Bend |

| Wall Thickness | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS / 3mm – 40mm |

| Buttweld Fittingsing Radius | R = 1D, 1.5D, 2D, 3D, 5D, 6D, 8D, 10D |

| Product’s Angle | 0°~180° |

| Value Added Services | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Important Grades | ASTM A403 WP 304 / 304L / 304H / 316 / 316L / 317 / 317L / 321 / 310 / 347 / 904L |

| Production Materials | Stainless Steel, Alloy Steel, Carbon Steel, Duplex & Super Duplex Steel, Nickel Alloys, Cupro Nickel, Hastelloy, Titanium, SMO 254, Alloy 20, Inconel |