The prime global leader of Forged Pipe Fittings/Forged Fittings Manufacturers in India. Also, Alloy Steel Forged Fittings, Carbon Steel Forged Fittings & Stainless Steel Forged Fittings suppliers in Mumbai, Rajkot. Buy high-grade Socket Weld Fittings & Threaded Fitting from one of the prominent ISO certified company in India. Fitwel Industries LLP is one of the leading Forged Fittings Manufacturers in India and supplier of high-qualityforged fittings manufacturers in India And 304 Stainless Steel Socket Weld Fittings that are made from superior grade steel which have high tensile strength and corrosion resistant properties. Stainless Steel Forged Fitting Manufacturers in India is a versatile product by means of having an excellent resistance to atmospheric corrosion, to a lot of inorganic and organic chemicals. We are a leading stockist, Supplier, and Exporter of forged Pipe Fittings and Forged Fittings in all grades with high-quality material to manufacture the most durable and long-lasting forged Pipe Fittings Or Forged Fittings in India.

Forged Fittings are made of Stainless Steel A182 & Carbon Steel A105, or nickel alloy. These fittings are thicker, heavier and are intended for heavy industrial use.

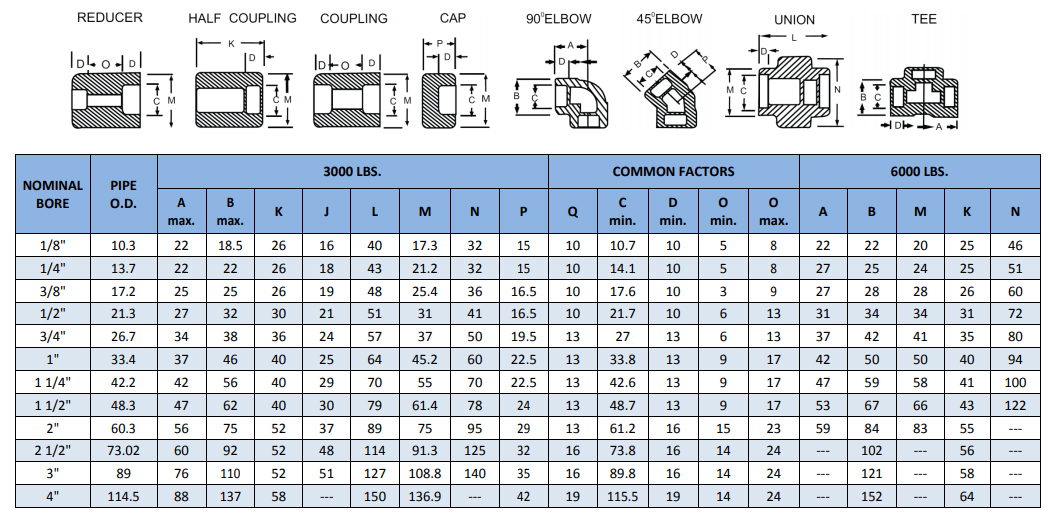

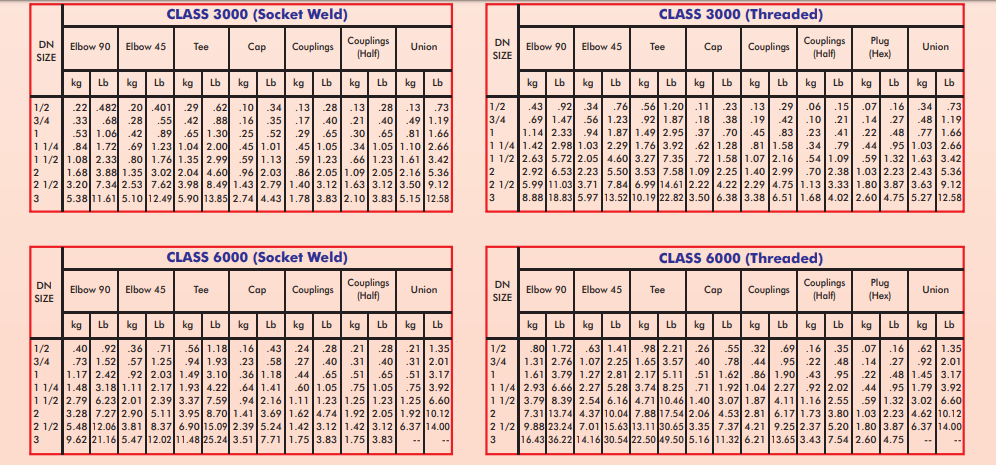

Forged Pipe Fittings are available in NPT or BSPT threaded or socket weld (SW) form in various steel grades. Forged steel pipe fittings (Socket Weld Forged Pipe Fittings and Threaded Forged Steel Pipe Fittings) are machined from solid forgings. The quality of the fittings is critical in that they are designed to withstand higher pressures. In designing forged fitting, the most important factors are uniformity of wall, wide bands, sharp threads properly chamfered, and unrestricted flow. We produce a wide range of threaded fittings and socket weld fittings such as forged elbow, forged cross, forged street elbow, forged tee, forged coupling, forged half coupling, forged end cap, forged plug, forged bushing, forged union, forged outlet, forged nipple, forged head plug, forged reducer insert, forged pipe nipple etc. Forged pipe fittings are produced as per ASME B 16.11, MSS-SP-79\ 83\ 95\97 with pressure ratings of 2000, 3000, 6000, and 9000 LBS. Generally, the raw material size for producing forged fittings is 19-85mm round bars. We are a specialist producer of socket weld and threaded fittings in stainless steel, carbon steel, alloy steel, and nickel alloys

The offered Forged Fittings Manufacturers in India are being made from finest quality of raw material and are obtainable in different lengths, sizes and dimensional specifications. They are extensively used in high-pressure applications. Forged Union are precision-engineered, durable, reliable, and exhibit resistance to heat and corrosion. They have a sturdy construction and are verified by professionals. The raw material for these Forged Coupling is acquired from renowned Manufacturer and suppliers in suitable quantities.

We offer this extensive range of Forged Fitting Suppliers to its clients as per their exact specifications along with prompt delivery services. The prices charged are reasonable and competitive enough to ensure that these fittings are attainable by all clients.

Forged Fittings are pipe fittings that are made from forged steel material. CS is heated to molten temperatures and placed in the dies. The heated steel is then machined into the forged steel fittings. High-strength forged products are extremely durable and resilient to climate factors. These types of pipe fittings produce a great seal in your piping systems that reduce the risk of leaks. With forged steel fittings deliver a fatigue strength of 37% higher.

Forged fittings come in a wide range of dimensions that are made for industrial use. They are available as socket weld fittings or threaded fittings. With the right supplier, you will have no problem finding cost-effective piping system parts.

If you are looking for the fittings that are going to give you that one and done results and years of worry-free function, forged steel is the way to go. You can use pricier titanium pipe fittings to get similar results but the cost to quality ratios just does not pan out.

Titanium fitting is a great option but they can be more costly than forged steel fittings which can easily drive project costs up. With forged steel you get:

You can get the high level of durability that you need for your piping systems without breaking the bank to do it. No one needs to tell you how important it is to keep material costs down. While one or two titanium pipe fittings won’t break the bank, when your project requires many fittings, the cost starts to rack up.

Forged Elbow is one of the common pipe fittings applied in the oil &gas industry. An elbow provides a change in material-flow direction. These forged elbows have a Center-to-Face dimension of 1.0 X diameter. They are typically used in tight areas where clearance is the main issue.

Elbow Fitting of steel pipe joints are used in industrial plants and are mainly manufactured by the hot mandrel bending from the raw material of straight steel pipe. Elbows are generally manufactured at elevated temperatures by means of pushing, expanding, and bending pipes simultaneously, using the inner tool of a mandrel.

ASTM A182 forged fittings equal tee, ANSI B16. Equal Tee is a forged fitting used for splitting and changing the flow direction of run pipe of 90 degrees. Moreover, these tee fittings do not need any special tubing preparation before application.

Forged Reducing Tee is either used to combine or split a fluid flow. Threaded Pipe Reducing Tee has the same inlet and outlet sizes. Threaded Reducing Tee Fittings are used in different industries applications like chemical processing, oil refineries, petrochemical, and many other industries.

Forged Half Coupling is used for small bore branching from a vessel or large bore pipe. It can be threaded or socket type. It has a socket or thread end on only one side. A socket weld half coupling can be directly welded to a large bore pipe, to make a branch connection.

Forged Full Coupling is used for connecting small bore pipes. It used to connect pipe to pipe or pipe to swage or nipple. It can be threaded or socket ends types. A socket weld full coupling is used to join small-bore plain end pipes where the pipe spec requirement is socket weld.

Forged Pipe Union is a type of fitting equipment designed in such a way to unite two pipes that can be detached without causing any deformation to the pipes. Any kind of small diameter piping connections requiring a positive seal and easy assembly as well as disassembly is made with the help of pipe union.

Forged head plug are defined as the cap end of fractional tubes used in a large number of industries. These Forged Pipe Plugs are designed to insert into the end of the tubing to dead-end the flow. Various materials are used to manufacture high-quality tube plugs in a variety of end connections.

Forged Olets that means Forged Weldolet, Forged Threadolet, Forged Sockolet, Forged Elbolet etc, are used to create an outlet from a run pipe (the “header size”) to a branch pipe (the “outlet size”). Olets are branching fittings made by Fitwel. Forged Olets offer an alternate means of connecting into the main run and do not require reinforcement. Olets are pre-shaped to the curvature of the run pipe. Flat-based weldolets are available for connecting to pipe caps and vessel heads.

Forged steel pipe fittings, branch connections, couplets, elbolet, long weld neck flanges, everything you need for installing a piping system, maintaining a piping system, repairing a piping system, and modifying a piping system that you can all be found at fitwelindia,

We are the trusted industrial piping material resource that supports industrial piping activities with unmatched customer care, high-quality reliable forged fittings items, and materials. We ensure that you have the materials that you need to keep your piping system working at its optimal.

These Stainless Steel Socket Weld Fitting is a kind of T-300 series austenitic alloy, which has at least 8 percent nickel content and 18 percent chromium content in it. These 304 Stainless Steel Socket Weld Fitting are being made by using stainless steel which make these fittings anti-corrosive, make them neutral and also withstand extreme temperature conditions. Our Stainless Steel Forged Fitting is made with Stainless Steel that possess chromium in a higher amount to resist the oxidizing agent and chemical corrosive agent. It maintains a stable amount of nitrogen, manganese, silicon for excellent strength to hold high pressure. These Stainless Steel Threaded Fitting is suitable for compression fittings, and it has a thick layer that serves a complete leakage-free performance. Stainless Steel 304 Forged Fitting have excellent thermal stability, do not deform easily in high-temperature applications.

As we are top leading manufacturer of 304 Stainless Steel Socket Weld Fittings, we provide ultimate convenience to our clients by producing high quality Stainless Steel 304 Forged Fittings which is offered at reasonable and competitive prices. Stainless Steel is a corrosion-resistant steel alloy that has different grades and surface finishes. Stainless Steel Forged Fittings are defined as an essential part used in pipe fittings. 304 Stainless Steel Socket Weld Fittings are lightweight and easy to install.

They are also corrosion and abrasion-resistant. These Unions are utilized in various application industries that require joining or two heavy-duty metal parts. These Stainless Steel 304 Forged Couplings can be used in ship buildings, fats and fertiliser industries and chemical industries. It is reliable and has high tolerance capacity. Stainless Steel 304 Forged Elbows that make 45° or 90° changes of direction in the run of the pipe are widely accepted by the clientele due to their effective usage and reasonable prices. Stainless Steel 304 Forged Fittings are produced by using modern technology and high-quality raw materials that assure compliance with international standards of these fittings. We ensure customer satisfaction. Also, We offer a wide range of Stainless Steel ASTM A182 304 Forged Fittings such as SS 304 Forged Elbow, SS 304 Equal Tee, SS 304 Coupling, SS 304 Pipe Cap, SS 304 Union, SS 304 Bushing, SS 304 Plug, SS 304 Pipe Nipple, SS 304 Street Elbow.

The offered 304 Stainless Steel Forged Socket Weld Fittings are manufactured from best quality of raw material and are available in various sizes, lengths and dimensional specifications. They provide ultimate convenience to their clients by producing high-quality Stainless Steel 304 Forged Fittings which are offered at reasonable and competitive prices. Stainless Steel is a corrosion-resistant steel alloy that has different grades and surface finishes. Stainless Steel Forged Fittings are defined as an essential part used in pipe fittings. Stainless Steel 304 Socketweld Unions are lightweight and easy to install.

This grade of Stainless Steel is commonly used for weldments where its immunity to carbide precipitation ensures maximum resistance to corrosion. The Stainless Steel Forged Fitting under this grade is versatile and produced from raw materials purchased from renowned vendors. The consistency that we have maintained with regards to responsive after-sales service and the quality of products offered by them to the clients is what ensures customer loyalty. They provide the above-mentioned products in varied sizes, shapes, and thicknesses to comply with the different needs of the clients. Also, We offer a wide range of Stainless Steel ASTM A182 Forged Fitting such as Stainless Steel Forged Elbow, Stainless Steel Equal Tee, Stainless Steel Coupling, Stainless Steel Pipe Cap, Stainless Steel Union, Stainless Steel Bushing, Stainless Steel Head Plug, Stainless Steel Pipe Nipple, Stainless Steel Street Elbow. We offer the same at highly competitive prices. Meanwhile, our SS Forged Fittings are also being made from supreme quality of raw material in international standards. These fittings are also at length used in diverse industries.

As an ISO certified company that looks out for all the needs of its customers is a rising manufacturer and distributor of Stainless Steel Forging Fitting. It adheres to all the national and international standards that must be followed by any company that wishes to reach a level of excellence and acquire customer loyalty. SS Forged Fittings is a molybdenum austenitic alloy that has great resistance to corrosion and chloride environments.

The iron-based alloys known as Steel are arguably the most widely used materials in construction and manufacturing worldwide. A wide variety of Steel grades, each with unique chemical compositions, have been created, based on the requirements of the end use a steel component must serve.

Forged Fittings are made of Stainless Steel A182 and Carbon Cteel A105, or nickel composite. These fittings are thicker, heavier and are planned for substantial modern use.

Stainless Steel Forged Pipe Fittings are accessible in NPT or BSPT strung or attachment weld (SW) structure in different steel grades. Stainless steel pipe fittings (Socket Weld Forged Pipe Fittings and Threaded Forged Steel Pipe Fittings) are machined from b forgings. The nature of the fittings is basic in that they are intended to withstand higher pressing factors. In planning stainless fitting, the main components are consistency of divider, wide groups, sharp strings appropriately chamfered, and unhindered stream. We produce a wide scope of strung fittings and attachment weld fittings, for example, elbow, cross, road elbow, tee, coupling, half coupling, cap, plug, bushing, association, power source, sage areola, bull plug, reducer embed, pipe areola etc. Stainless Steel Forged Fittings are delivered according to ASME B 16.11, MSS-SP-79\ 83\ 95\97 with pressure evaluations of 2000, 3000, 6000, and 9000 LBS. By and large, the crude material size for delivering produced fittings is 19-85mm round bars. We are an expert maker of attachment weld and strung fittings in hardened steel, carbon steel, composite steel, and nickel alloys

Stainless steel forged pipe fittings are essential components of some industrial or commercial systems, making the joining of two or more pipes, possible. Piping systems less than 2 or 4 inches in diameter generally use forged fittings and differ from buttweld fittings used for piping systems with larger diameters. These Stainless steel forged fittings manufacturer are produced for the purpose of offering complete convenience to the clients. Stainless Steel consists of 18% Chromium, 8% Nickel and it has lower carbon content. Its main features are its high strength and resistance to corrosion. Stainless steel Forged Elbows are created using the latest technology.

The manufacturing process of stainless steel forged pipe fittings involves the application of thermal and mechanical energy to shape solid stainless steel blanks into functional shapes within the tolerances established by the applicable specifications. These forged fittings are available in a wide range of sizes and diameters, and there are several shapes of forged fittings to cater to any type of pipe joint.

Steel forged fittings have to meet several requirements to ensure optimal functionality as socket weld or threaded fittings.

These steel forged fittings have to be corrosion-resistant. If a socket weld or threaded steel forged fitting is susceptible to rust, premature deterioration and leaks can result. Corrosion can also make it difficult to install or remove a threaded steel forged fitting.

Stainless steel forged fittings should also be lightweight, but durable and abrasion-resistant during high-temperature services or strenuous weather conditions. Additionally, stainless steel forged fittings should be suitable for installing high-pressure (3,000lb, 6,000lb, and 9,000lb) piping systems.

Each fitting has a class grading of 3000, 6000, or 9000, representing the maximum pressure that the stainless steel forged fitting can withstand. Pipes in schedule 80/XS require class 3000 fittings, pipes in schedule 160 require class 6000 fittings, and XXS pipes with thicker walls require class 9000 fittings.

Stainless steel grades that generally meet these requirements are in the 300 series, including, among others, 304, 304L, 309, 310, 316, 316L, 317L, 321, and 347. The L-grades offer additional corrosion resistance after welding. Some socket weld steel forged fittings are 304L stainless steel.

Careful application of ASME B16.11 and ASTM A182 standards will help users comply with all the applicable regulations while achieving optimal cost, operational, and safety benefits from steel forged fittings. The most common material grades are ASTM A105 and ASTM A350 LF/1/2/3/6 for low-temperature applications and ASTM A182 for high-temperature, corrosive applications.

There are two basic types of stainless steel forged fittings, namely:-

With threaded stainless steel fittings, pipe and fitting join to each other using threaded sections. One or both components must be rotated to engage the threads and fully close any gap between them. The strength of the joint is dependent upon the strength of the engaged threads. With socket weld fittings, the fitting connects to the pipe with pipe entering a shallow depression in the fitting. The gap is then closed with a “fillet weld” which involves applying heat and filler metal to provide a seal, metal melted and re-solidified to close the gap.

Stainless steel forged fittings are available in a variety of shapes and sizes including 45-degree elbows, 90-degree elbows, tees – which can be equal (straight) or reducing, lateral or Y-shaped pipe fittings to branch a pipe at 30 degrees, cross fittings to connect four pipes, plugs or caps to blind pipes, half or full couplings to join pipes, and reducer inserts to reduce the bore size.

In common use in are several types of thread forms including British Standard Pipe (BSP), National Pipe Tapered (NPT), and ISO Pipe and Port Size Metric sizes. These threads are not compatible with each other.

Threaded pipe forged fittings are suitable for applications such as cooling, fire protection, and water distribution. If the pipe system manages fluids with continually changing temperatures, threaded pipe fittings are not ideal as temperature fluctuations can cause the fitting to crack in the thread forms.

Stainless Steel Socket Weld Fittings are family members of high pressure pipe fittings, which available in rating of Class 3000lb, 6000lb and 9000lb. They are used in areas where pipe-work is permanent and are designed to provide good flow characteristics. Usually in conjunction with with ASME Pipe and are available in the same size range.

We produced forged steel fittings in accordance with ASME B16.11. The B16.11 standard covers pressure-temperature ratings, dimensions, tolerances, marking, and material requirements for forged carbon and alloy stainless steel. The chemical and mechanical property requirements are conform to ASTM A105, A182 or A350.

Socket weld forged fittings may be considered more permanent than threaded forged fittings. Welded joints are considered more relaiable if the welding process is performed correctly, providing a stronger joint attachment. The drawback of fittings of this type is the time and labor for installation. Typical applications for socket weld forged fittings include steam and other gases, toxic fluids and acids, and explosive liquids and gases where highest connection strength and leak prevention are critical.

| Description | Class Designation | ||

| 3000 | 6000 | 9000 | |

| Elbows 45 and 90 degrees, Tees, Crosses, Couplings, Half-Couplings, End or Pipe Caps |

1/2 - 4 | 1/2 - 2 | 1/2 - 2 |

| 1/2 - 4 | 1/2 - 2 | 1/2 - 2 | |

| 1/2 - 4 | 1/2 - 2 | 1/2 - 2 | |

| Pipe Size by Wall Thickness |

SCH 80 / XS | SCH 160 | XXS |

Several specifications apply to stainless steel forged fittings. The American Society of Mechanical Engineers (ASME) B16.11 specifications cover forged fittings to fit ASME B36.10 and ASME B36.19 pipes.

This specification covers the material requirements, dimensions, ratings, marking, and tolerances for socket weld forged fittings and threaded forged fittings. Users should apply B16.11 specifications in conjunction with equipment that other volumes of the ASME B16 series of standards describe.

ASTM A182 is another specification that applies to forged pipe fittings. Specifically, ASTM A182 covers forged fittings, forged- or rolled alloy pipe flanges, stainless steel pipe flanges, valves, and other components for high-temperature service.

ASTM A 182 also applies to forged fittings for use in pressure systems. ASTM A182 include forged fittings of ferritic, martensitic, austenitic, and duplex stainless steels.

Stainless Steel Forged Fittings is a material resulting from alloying iron and carbon under extremely high pressure. Forged steel has less surface porosity, a finer grain structure, more tensile and fatigue strength, and greater ductility than any other processed steel.

Applications of Stainless Steel Forging Fittings are Chemical Processing, Food Processing, Photographic, Textile Finishing Machinery, Pharmaceutical and Marine Exterior Trim. SS Forging Fitting is an extra-low carbon version of the alloy material grade. It minimizes harmful carbide precipitation due to welding. It is tested well on various quality parameters. Stainless Steel Forged Pipe Elbows are durable and are highly resistant to corrosion. These SS Forged Fittings are manufactured in all standard dimensions.

Cannot produce porous bearings, sintered carbides, or parts with a mix of multiple metals. Cannot produce small, finely designed parts without machining. Die production is expensive, making the economics of short production runs undesirable.

Size : 1/8” NB to 4” NB (Socketweld & Screwed-Threaded)

Specifications : ASTM A182 / ASME SA182

Standards : ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799

Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Type : Socketweld Fittings, Screwed-Threaded Fittings

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| Grade | C | Mn | Si | P | S | Cr | Ni | MO |

| SS 304 | 0.08 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 10.5 | Balance |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 304 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

ASTM A182 304 Forged Fittings are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of ASTM A182 304 Stainless Steel Forged Pipe Fittings through a worldwide network of stock-keeping branches. These ASTM A182 304 Forged Fittings is use in various industries like :-