Fitwel Industries LLP is the prominent manufacturers, suppliers, and exporter of EN, ASME, DIN, ANS, BS Flanges. With a thorough understanding of the relevant industry, we are offering a wide range of Carbon Steel Flanges. With the help of our technical advancement skills, we offer an extensive range of these flanges. Our offered range has excellent quality and is completely inspected before being made available on the market. Our offered flanges are checked in terms of high quality so as to deliver a faultless range. Known for their corrosion-free surface, these products are very popular among clients. Furthermore, our team members make it a point to check products on strict quality parameters so as to be sure of their perfect durability. The offered range of flanges are fabricated by our experienced professionals are making use of high quality of raw materials, latest technology, and modern machinery.

Carbon Steel A105/A105N Flanges, which is Inspected by the American Society for testing materials, classifies as a standard that covers forged Carbon-Steel piping parts that also include flanges, which are serviceable in pressure systems at room temperatures as well as temperatures higher than it. We produce Carbon Steel A105/A105N Blind Flanges manufacturers which are successful in pressure bearing and sealing pipe ends in heavy pressure applications like hydraulic systems since they have maximum bending stress at the center. Carbon Steel Weld Neck Flanges is a perfect material that is used in manufacturing vital components. These carbon flanges suppliers mumbai lead to a life expectancy far in excess of that is achieved by standard steels. The main weakness that is inherent in these Carbon Steel Flanges Manufacturer Mumbai is it boasts relatively low strength and thus relatively low resistance to stress corrosion cracking.

Carbon Steel Flanges manufacturer in India is exposed to more durable bases such as sodium hydroxide at high concentrations and temperatures then it will likely experience some etching and cracking. And his occurs especially with solutions that contain chlorides such as sodium hypochlorite. We are providing all types of flanges like high, low, and medium flanges. These carbon steel flanges suppliers India offer exceptional strength and durability to our products. We are also offering these carbon steel flanges manufacturers Vasai in customized sizes and standard specifications as per the international quality standards as per the requirement of our valuable customers at competent prices.

In the international metal market today the carbon steel flanges manufacturers Ahmedabad have gotten greater appreciation because of their superiority in it in terms of quality. The product to global and domestic buyers is supplied at reasonable rates. Fitwel Industries LLP is a legally certified industry is making the product on the principles of safety and quality. We are supplying the carbon steel flanges in various specifications so that the demand for various applications can be very well satisfied. No doubt one seeking to buy it in bulk can get it at very fewer rates easily.

It is highly appreciated because of being durable, flexible, long-lasting, dimensional accuracy, rugged construction, withstanding heavy loads, can hold high temperatures. The product is fabricated in such a way that it assures to be excellently corrosion, pitting, crevice corrosion, stress corrosion cracking and erosion resistant.

Many testing effectively is conducted by using modern tools so that the producers can bring out a better quality of the product. The tests performed are IGC/PMI test, flattening/flaring test, mechanical test, hardness test, chemical analysis, pitting resistant test, etc.

The documents that the suppliers are assuring in offering to the buyers are meant that clearly states the high quality of fabrication of flanges is done. It is commercial invoice, fumigation certification, heat treatment chart, guarantee letter, fumigation certification, raw material test report, certificate of origin, packaging list, etc.

Carbon steel is an iron-carbon alloy, which contains up to 2.1 wt.% carbon. For carbon steels, there is no minimum specified content of other alloying elements, however, they often contain manganese. The maximum manganese, silicon, and copper content should be less than 1.65 wt.%, 0.6 wt.% and 0.6 wt.%, respectively.

Low-carbon steel is the most widely used form of carbon steel. These steels usually have a carbon content of less than 0.25 wt.%. They cannot be hardened by heat treatment (to form martensite) so this is usually achieved by cold work.

Carbon steels are usually relatively soft and have low strength. They do, however, have high ductility, making them excellent for machining, welding, and low cost.

High-strength, low-alloy steels (HSLA) are also often classified as low-carbon steels, however, also contain other elements such as copper, nickel, vanadium, and molybdenum. Combined, these comprise up to 10 wt.% of the steel content. High-strength, low-alloy steels, as the name suggests, have higher strengths, which are achieved by heat treatment. They also retain ductility, making them easily formable and machinable. HSLA is more resistant to corrosion than plain low-carbon steels.

Medium-carbon steel has a carbon content of 0.25 – 0.60 wt.% and manganese content of 0.60 – 1.65 wt.%. The mechanical properties of this steel are improved via heat treatment involving austenitizing followed by quenching and tempering, giving them a martensitic microstructure.

Heat treatment can only be performed on very thin sections, however, additional alloying elements, such as chromium, molybdenum, and nickel, can be added to improve the steel's ability to be heat-treated and, thus, hardened.

Hardened medium-carbon steels have greater strength than low-carbon steels, however, this comes at the expense of ductility and toughness.

High-carbon steel has a carbon content of 0.60– 1.25 wt.% and manganese content of 0.30 – 0.90 wt.%. It has the highest hardness and toughness of carbon steel and the lowest ductility. High-carbon steels are very wear-resistant as a result of the fact that they are almost always hardened and tempered.

Tool steels and die steels are types of high-carbon steels, which contain additional alloying elements including chromium, vanadium, molybdenum, and tungsten. The addition of these elements results in very hard wear-resistant steel, which is a result of the formation of carbide compounds such as tungsten carbide (WC).

Carbon Steel Flanges manufacturer of different Carbon steel materials. There are different grades to the Carbon steel depending on the material composition and the mechanical properties vary. Fitwel Industries LLP is a leading manufacturer and supplier of these flanges. Carbon Steel Flange is a forged, or it is called a cast ring which is designed to connect different sections of the pipe or any other machinery that requires an intermediate connecting point. These flanges are in massive demand in the market because of their tensile strength and surface finishing.

A Carbon Steel Class 150 flange Mumbai is a method of connecting pipes, valves, pumps, and other equipment to form a piping system. It also provides easy access for cleaning, inspection, or modification. Carbon Steel Flanges are usually welded or screwed. Flanged joints are made by bolting together two Flanges with a gasket between them to provide a seal.

Our manufacturing facilities are well equipped to manufacture various types of flanges namely:

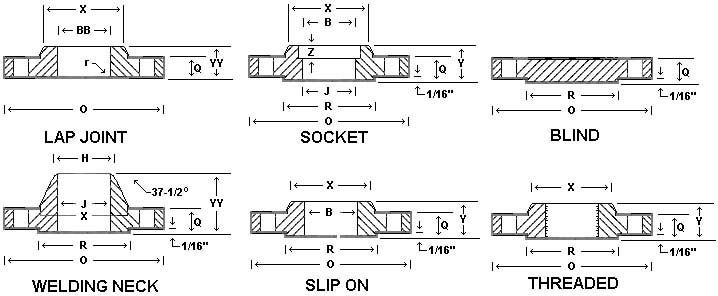

These are easily fitted and welded into different pipes. Slip on pipe flange is slipped over the Pipe and then welded both inside and outside to provide sufficient strength and prevent leakage. These flanges are ideal for lower pressure applications.

Carbon Steel Weld Neck flanges have a long tapered hub and are often used for high pressure applications. These flanges are designed to be joined to a Piping system by Bun Welding. The Neck, or Hub, transmits stresses to the Pipe, reducing stress concentrations at the base of the Flange.

A Carbon Steel Blind flange is a round plate that has all of the relevant boltholes but no centre hole, and because of this feature this flange is used to close off the ends of the piping system and pressure vessel openings. It also permits easy access to vessels or Piping systems for inspection purposes.

These Carbon Steel Socket Weld Flanges are attached by inserting the pipe into the socket end. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. Socket-weld pipe flanges are mainly used for smaller sizes of high-pressure pipes.

Carbon Steel Threaded flanges are similar to slip-on pipe flanges except the bore of threaded pipe flange has tapered threads. These flanges are ideal for relatively low pressure piping systems. Threaded flanges are used with pipes that have external threads. The benefit of these pipe flanges is that they can be attached without welding.

Carbon Steel Lap Joint Flanges slide over the pipe and are most commonly used with Stub End Fittings. A pipe is typically welded to the Stub End and the Lap Joint pipe flange is free to rotate around the stub end. Lap Joint pipe flanges are often used for applications that require frequent dismantling. Threaded pipe flanges are often used for small diameter, high-pressure requirements.

Carbon Steel Orifice Flanges are used instead of standard pipe flanges when an orifice plate or flow nozzle must be installed. Pairs of pressure tappings are machined into the orifice flange, making seperate orifice carriers or tappings in the pipe wall necessary.

In addition to these we also manufacture Orifice Flange, Stub-end fittings, plate flanges, backup flanges, Beveled ID flanges, and Reducing flanges.

Our Carbon Steel A105 Flanges are having some great features.

Check prices before you buy A105 Carbon Steel Flanges in India, Vasai, Mumbai, UK, UAE, Singapore, Europe, etc, including ASTM A105 Grade WPB Forged Carbon Steel flanges, and more than 100 types of Forged Carbon Steel fittings, You can also receive a free sample of ASTM A105 Forged & Plate Pipe Flanges.

Size : 1/2"NB TO 48 "NB

Specifications :ASTM A105 / A350 LF2 / ASTM A694

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Standards : ASTM, ASME Flanges, ANSI Flanges, DIN Flanges, EN Flanges, BS Flanges etc.

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS DIN Standard ND 6,10, 16, 25, 40

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Grades : F42, F46, F52, F60, F65, F70, A36, A516 Gr. 70,60.

| Specifications | ASTM A105 / ASME SA105, A105N |

|---|---|

| ASME B16.5 Carbon Steel Flanges size range | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

| Carbon Steel Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Carbon Steel Flanges Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Carbon Steel Flanges Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Carbon Steel Flanges Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Carbon Steel Flanges Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Carbon Steel Flanges Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Carbon Steel Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Carbon Steel Flanges |

|

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, , Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS Carbon Steel Flanges Threaded Flanges, Socketweld Flanges, Slip-On Flanges, Blind Flanges, Weld Neck Flanges |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Specialized manufacturer of |

|

| Carbon Steel Flanges Standard | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Key markets and industries for Carbon Steel Flanges |

|

| Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Carbon Steel Flanges Application |

|

| Element | Carbon | Silicon/b> | Manganese | Phosphrous | Sulphur | Molybdenum | Chromium | Nickle |

| Weight % | 0.035 | 0.60-1.05 | 0.035 | 0.40 Max | 0.40 Max | 0.40 | 0.12 | 0.08 Max |

|

Carbon content (wt.%) |

Microstructure |

Properties |

Examples |

|

|---|---|---|---|---|

|

Low-carbon steel |

< 0.25 |

Ferrite, pearlite |

Low hardness and cost. High ductility, toughness, machinability and weldability |

AISI 304, ASTM A815, AISI 316L |

|

Medium-carbon steel |

0.25 – 0.60 |

Martensite |

Low hardenability, medium strength, ductility and toughness |

AISI 409, ASTM A29, SCM435 |

|

High-carbon steel |

0.60 – 1.25 |

Pearlite |

High hardness, strength, low ductility |

AISI 440C, EN 10088-3 |

| Properties | Imperial | Metric |

| Tensile strength | 86300 psi | 595 MPa |

| Modulus of elasticity | 29000 ksi | 200 GPa |

| Yield strength | 37700 psi | 260 MPa |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Hardness, Rockwell B | 85 | 85 |

| Elongation at break (in 50 mm) | 55% | 55% |

Forged and Plate Flanges

| Products | Size | |

| ASTM A105 Carbon Steel Slip-On Flanges | ASTM A105 Carbon Steel Threaded Flanges | Sizes 1/2″ – 48″ Raised Face or Flat Face |

| ASTM A105 Carbon Steel Weld Neck Flanges | ASTM A105 Carbon Steel Socket Weld Flanges | |

| ASTM A105 Carbon Steel Blind Flanges | ASTM A105 Carbon Steel Reducing Flanges | |

| ASTM A105 Carbon Steel Lap Joint Flanges | ASTM A105 Carbon Steel Plate Flanges | |

| ASTM A105 Carbon Steel Orifice Flanges | ASTM A105 Carbon Steel Forged Flanges | |

| ASTM A105 Carbon Steel Ring Type Joint Flanges | ASTM A105 Carbon Steel Square Flanges | |

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

| Carbon Steel Flanges | Carbon Steel EN 1092-1 Flanges |

| Carbon Steel BS 4504 Flanges | Carbon Steel A105N Forged Flanges |

| Carbon Steel A105 Flanges | Carbon Steel Slip on Flanges |

| Carbon Steel Flat Flange Suppliers | ANSI Carbon Steel Blind Flange |

| Carbon Steel A105N Weld Neck Flanges Dealer | Carbon Steel Socket weld Flanges Exporter |

| Carbon Steel Long Weld Neck Flanges Stockholder | CS ASTM A105 Threaded Flanges Distributors |

| Carbon Steel ASTM A105 Reducing Flanges | Carbon Steel Ring Type Joint Flanges Manufacturer |

| Carbon Steel A105 Orifice Flange | ASTM A105 Carbon Steel Spectacle Blind Flanges |

| ASME SA105 Carbon Steel WNRF Flange | Carbon ASTM A105N SORF Flanges |

| ANSI B16.5 Carbon Steel RTJ Flanges | Carbon Steel Screwed Flanges Stockist |

| ASTM A105N Carbon Steel Lap Joint Flanges | ASME SA105 Carbon Steel BLRF Flange |

| Carbon Steel Raised Face Flanges | ASTM A105 Carbon Steel Nipoflange |

| A105 Carbon Steel Square Flanges | ASME SA105N Carbon Steel SWRF Flange |

| Steel Tongue & Groove Flanges | Carbon Steel Male & Female Flanges |

| A105 Carbon Steel DIN Flanges | Carbon Steel ASME B16.5 Flanges |