Fitwel Industries LLP is one of the recognized leading Carbon Steel Pipe Fittings Manufacturer in Mumbai, India. We manufacture these Carbon Steel Buttweld Fittings on a large scale and make them available to buyers across the world at economical prices. Carbon Steel Buttweld Fittings are made in distinct shapes, sizes, and specifications. Our customized range also has been appreciated by our customers as they had proved their usability for various applications.

Carbon Steel Pipe Fittings Manufacturers in Mumbai are made up of steel that has 2.1% of carbon by weight at least. This percentage of carbon makes it excellently weldable and formable. We develop various forms of Carbon Steel Pipe Fittings that are used in different applications. For supplying fluid from one direction to the other with the same diameter, the Carbon Steel Equal Tee Fittings serve as the best option.

Carbon Steel Pipe Fittings manufacturer in India has, such as compact size, accurate dimensions, rustproof and more. The manufacturing operations are performed at a highly advanced production plant that has the latest machines and equipment that are being operated by trained and skilled operators. Our workforce has vast experience, and they are expert in manufacturing Carbon Steel Pipe Fittings Suppliers with accuracy. These Fittings show excellent strength when used at a higher temperature. The hardness of these Fittings also enhances at a higher temperature. Carbon Steel Buttweld Elbow & Carbon Steel Buttweld Tees are the highly demanded Carbon Steel Buttweld Fittings. Following are the features of these;-

The properties that need to be considered by designers when specifying carbon steel construction products are:-

Our rich technical experience and organized production procedures have helped us become one of the most trusted suppliers of carbon steel fittings and flanges to large shipyards, fabrication companies, chemical plants, oil refineries, machinery manufacturers, textile, and fluid transportation companies among others. In general, carbon steel pipe fittings are widely used for applications that do not require materials with higher resistance to corrosion such as stainless steel and nickel alloys. Carbon steel products corrode and get rusted easily if exposed to water. Here at Fitwel, we offer a complete range of pipe fittings such as carbon steel reducer, carbon steel elbow, carbon steel tee, carbon steel cross, carbon steel stub ends, and carbon steel pipe bends. Carbon steel pipe bends with a bending radius 3D, 5D and 7D are most commonly used across various industries. Our key pipe bend products include high-quality carbon steel long radius piggable bends, seamless long radius piggable bends, and welded long radius piggable bends.

As a leading Carbon Steel Fittings manufacturer in India, we do supply different types, dimensions, grades, and variations of the Carbon Steel Elbow Sch 40 and another fitting. The elbows are one of the commonly used fittings. The carbon steels are used for their high toughness and high wear resistance. The Schedule 10 carbon steel buttweld fittings are some of the low schedule fittings. The schedules can range from 5 to 160 and XXS.

The schedules are relationships between the wall thickness and the outer diameter. The Carbon steel seamless fittings can range from ½ inches to 48 inches in outer diameter. They belong to the B16.5 standard. There are different grades of carbon steel that are used for the production of the Schedule 10 carbon steel pipe fittings. The types vary such as bends, elbows, couplings, crosses, and tees. These fittings are made to connect pipes together. The end cap however is the one fitting that closes a line.

ASTM A234 WPB is Standard Specification for steel pipe fittings includes carbon and alloy steel material for moderate and high-temperature services. ASTM A234 WPB Sch 40 Fittings covers carbon steel fittings of welded and seamless construction secured by the most recent amendment of ASME B16. 9, B16.

A234 WPB Carbon Steel Fittings is additionally exceedingly corrosion-resistant, have low string friction, and valuable where high alloyed steel is required. We are one of the prominent providers and dealers of these premium qualities ASTM A234 WPB Seamless Pipe Fitting, which is additionally utilized in Manufacturing plants, Difficult designing firms, Steel plants, and so on. ASTM A234 WPB is a Standard Specification for steel pipe fittings that includes carbon and alloy steel material for moderate and high-temperature services. ASTM A234 WPB Sch 40 Fittings covers carbon steel fittings of welded and seamless construction secured by the most recent amendment of ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97.

Carbon steel is an iron-carbon alloy, which contains up to 2.1 wt.% carbon. For carbon steels, there is no minimum specified content of other alloying elements, however, they often contain manganese. The maximum manganese, silicon, and copper content should be less than 1.65 wt.%, 0.6 wt.% and 0.6 wt.%, respectively.

Low-carbon steel is the most widely used form of carbon steel. These steels usually have a carbon content of less than 0.25 wt.%. They cannot be hardened by heat treatment (to form martensite) so this is usually achieved by cold work.

Carbon steels are usually relatively soft and have low strength. They do, however, have high ductility, making them excellent for machining, welding, and low cost.

High-strength, low-alloy steels (HSLA) are also often classified as low-carbon steels, however, also contain other elements such as copper, nickel, vanadium, and molybdenum. Combined, these comprise up to 10 wt.% of the steel content. High-strength, low-alloy steels, as the name suggests, have higher strengths, which are achieved by heat treatment. They also retain ductility, making them easily formable and machinable. HSLA is more resistant to corrosion than plain low-carbon steels.

Medium-carbon steel has a carbon content of 0.25 – 0.60 wt.% and manganese content of 0.60 – 1.65 wt.%. The mechanical properties of this steel are improved via heat treatment involving austenitizing followed by quenching and tempering, giving them a martensitic microstructure.

Heat treatment can only be performed on very thin sections, however, additional alloying elements, such as chromium, molybdenum, and nickel, can be added to improve the steel's ability to be heat-treated and, thus, hardened.

Hardened medium-carbon steels have greater strength than low-carbon steels, however, this comes at the expense of ductility and toughness.

High-carbon steel has a carbon content of 0.60– 1.25 wt.% and manganese content of 0.30 – 0.90 wt.%. It has the highest hardness and toughness of carbon steel and the lowest ductility. High-carbon steels are very wear-resistant as a result of the fact that they are almost always hardened and tempered.

Tool steels and die steels are types of high-carbon steels, which contain additional alloying elements including chromium, vanadium, molybdenum, and tungsten. The addition of these elements results in very hard wear-resistant steel, which is a result of the formation of carbide compounds such as tungsten carbide (WC).

Our Carbon Steel Buttweld Pipe Fittings are having some great features.

Check prices before you buy A234 WPB Carbon Steel Fittings in India, India, Mumbai, UK, UAE, Singapore, Europe, etc, including ASTM A234 Grade WPB Seamless, ASTM A234 WPB Sch 40 Fittings WPB Carbon Steel fittings, and more than 100 types of WPB Carbon Steel fittings, You can also receive a free sample of ASTM A234 WPB Seamless Pipe Fitting.

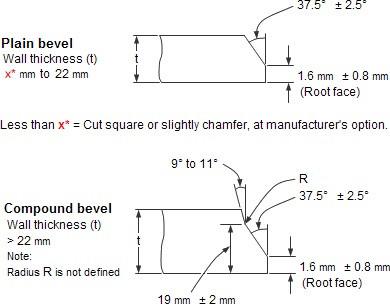

All welded pipe fittings have bevelled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases.

There are two types of bevels;-

| Grade | C | Mn | P | S | <Si | Cr | Mo | Ni | Cu | V | Nb |

| WPB | 0.3 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WPC | 0.35 | 0.29-1.06 | 0.05 | 0.058 | 0.1min | 0.4 | 0.15 | 0.4 | 0.4 | 0.08 | 0.02 |

| WP11 CL1 | 0.05-0.15 | 0.30-0.60 | 0.03 | 0.03 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

| WP11 CL2/3 | 0.05-0.20 | 0.30-0.80 | 0.04 | 0.04 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 | - | - | - | - |

|

Carbon content (wt.%) |

Microstructure |

Properties |

Examples |

|

|---|---|---|---|---|

|

Low-carbon steel |

< 0.25 |

Ferrite, pearlite |

Low hardness and cost. High ductility, toughness, machinability and weldability |

AISI 304, ASTM A815, AISI 316L |

|

Medium-carbon steel |

0.25 – 0.60 |

Martensite |

Low hardenability, medium strength, ductility and toughness |

AISI 409, ASTM A29, SCM435 |

|

High-carbon steel |

0.60 – 1.25 |

Pearlite |

High hardness, strength, low ductility |

AISI 440C, EN 10088-3 |

| Properties | Imperial | Metric |

| Tensile strength | 86300 psi | 595 MPa |

| Modulus of elasticity | 29000 ksi | 200 GPa |

| Yield strength | 37700 psi | 260 MPa |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Hardness, Rockwell B | 85 | 85 |

| Elongation at break (in 50 mm) | 55% | 55% |

| Pipe | Fittings | Flanges | Valves | Bolts & Nuts |

|---|---|---|---|---|

| A106 Gr A | A234 Gr WPA | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A106 Gr B | A234 Gr WPB | A105 | A216 Gr WCB | |

| A106 Gr C | A234 Gr WPC | A105 | A216 Gr WCB |

Notes:

Size : ½”NB to 48″NB in Sch 10s, 40s, 80s, 160s, XXS.

Specifications : ASTM A234 / ASME SA234

Low Temperature Steel : A420 WPL3 / A420 WPL6

Standards : ANSI/ASME B16.9, B16.28, MSS-SP-43.

Schedules : Sch.10 to Sch.XXs

Type : Seamless / Welded / Fabricated

Grades : WPBW, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.